![[US Patent & Trademark Office, Patent Full Text and Image Database]](United States Patent 5,598,663.files/patfthdr.gif)

| United States Patent |

5,598,663 |

| Kikuchi |

February 4, 1997 |

Hydroponic nutrient solution control system

Abstract

A hydroponic nutrient solution control system capable of performing the

nutrient solution control automatically, accurately, effectively, and

efficiently. In the system, the supplies of the acid nutrient ion ingredient

solutions and the alkali nutrient ion ingredient solutions from the acid

solution tanks and the alkali solution tanks to the nutrient solution tank are

controlled according to the pH measured by the pH meter and the ion

concentrations measured by the ion analyzer. The system may also controls the

supplies of the high concentration nutrient solutions and the water from the

high concentration nutrient solution tanks and the water supply according to the

electrolytic conductivity measured by the electrolytic conductivity meter.

| Inventors: |

Kikuchi; Hiroshi (Tokyo-to, JP) |

| Assignee: |

Kabushiki Kaisha Toshiba (Kawasaki, JP)

|

| Appl. No.: |

301039 |

| Filed: |

September 6, 1994 |

Foreign Application Priority Data

|

Dec 12, 1989[JP] |

1-320637 |

| Current U.S. Class: |

47/62N |

| Intern'l Class: |

A01G 031/00 |

| Field of Search: |

47/62 N,1.01 137/1,5

|

References Cited [Referenced

By]

U.S. Patent Documents

| 4149970 |

Apr., 1979 |

Atkins |

47/62. |

| 4152215 |

May., 1979 |

Yoshino |

47/62. |

| 4294037 |

Oct., 1981 |

Mosse |

47/62. |

| 4320594 |

Mar., 1982 |

Raymond |

47/62. |

| 4926585 |

May., 1990 |

Dreschel |

47/62. |

| 4992942 |

Feb., 1991 |

Bauerle |

47/62. |

| 5184420 |

Feb., 1993 |

Papadopoulos |

47/62. |

| Foreign Patent Documents |

| 0110111 |

Jun., 1984 |

EP |

47/62. |

| 7712467 |

May., 1978 |

NL |

47/62. |

| 2192875 |

Jan., 1988 |

GB |

47/62. |

Other References

Oakton WD-00661-10 "Dissolved Solid Tester" Considered

by the examiner to be an ion analyzer means as claimed by the applicant,

Devices of this sort have been in use in the hydroponics industry for many

years.

The ABC of NFT by Dr. Allen Coope pp. 47-89.

|

Primary Examiner: Raduazo; Henry E.

Attorney, Agent or Firm: Foley & Lardner

Parent Case Text

This application is a continuation, of application Ser. No. 08/145,305,

filed Nov. 3, 1993 now abandoned, which in turn is a continuation of application

Ser. No. 07/622,968, filed Dec. 6, 1990 and now abandoned.

Claims

What is claimed is:

1. A hydroponic nutrient solution control

system for controlling nutrient solution to be supplied to plants to be grown,

comprising:

nutrient solution tank means for containing the nutrient

solution to be supplied to the plants, to which the nutrient solution supplied

to the plants are returned;

pH meter means for measuring pH of the

nutrient solution in the nutrient solution tank means;

an ion analyzer

device for measuring an ion concentration of a plurality of nutrient ion

ingredients of the nutrient solution in the nutrient solution tank means

independent of other nutrient ion ingredients of the nutrient solution in the

nutrient solution tank means;

a plurality of acid solution tank means

for containing acid nutrient ion ingredient solutions, each acid solution tank

means separately containing an acid nutrient ion ingredient solution comprising

a compound selected from the group consisting of HNO.sub.3, H.sub.3 PO.sub.4,

and H.sub.2 SO.sub.4, to be supplied to the nutrient solution in the nutrient

solution tank means;

a plurality of alkali solution tank means for

containing alkali nutrient ion ingredient solutions, each alkali solution tank

means separately containing an alkali nutrient ion ingredient solution

comprising a compound selected from the group consisting of KOH, Ca(OH).sub.2,

Mg(OH).sub.2, and NH.sub.4 OH, to be supplied to the nutrient solution in the

nutrient solution tank means; and

means for automatically controlling

supplies of the acid nutrient ion ingredient solutions and the alkali nutrient

ion ingredient solutions by selectively operating appropriate ones of the acid

solution tank means and alkali solution tank means, according to the pH measured

by the pH meter means and the ion concentrations measured by the ion analyzer

device.

2. The system of claim 1, wherein the controlling means controls

the supplies of the acid nutrient ion ingredient solutions and the alkali

nutrient ion ingredient solutions from the acid solution tank means and the

alkali solution tank means, such that when the pH measured by the pH meter means

is lower than a prescribed acceptable range, those alkali nutrient ion

ingredient solutions whose ion concentrations are measured to be relatively low

by the ion analyzer means are supplied from the alkali solution tank means,

whereas when the pH measured by the pH meter means is higher than a prescribed

acceptable range, those acid nutrient ion ingredient solutions whose ion

concentrations are measured to be relatively low by the ion analyzer means are

supplied from the acid solution tank means.

3. The system of claim 2,

wherein the controlling means also controls the supplies of the acid nutrient

ion ingredient solutions and the alkali nutrient ion ingredient solutions from

the acid solution tank means and the alkali solution tank means, when at least

one of the ion concentrations measured by the ion analyzer means is outside a

prescribed acceptable range, in order to bring said at least one of the ion

concentrations to the prescribed acceptable range.

4. The system of

claim 3, wherein the controlling means controls the supplies of the acid

nutrient ion ingredient solutions and the alkali nutrient ion ingredient

solutions from the acid solution tank means and the alkali solution tank means,

such that when at least one of the ion concentrations for positive ions measured

by the ion analyzer means is lower than the prescribed acceptable range, those

alkali nutrient ion ingredient solutions which contain said positive ions are

supplied from the alkali solution tank means, whereas when at least one of the

ion concentrations for negative ions measured by the ion analyzer means is lower

than the prescribed acceptable range, those acid nutrient ion ingredient

solutions which contain said negative ions are supplied from the acid solution

tank means.

5. The system of claim 3, wherein the controlling means

controls the pH of the nutrient solution in the nutrient solution tank means

again after the supplies of the acid nutrient ion ingredient solutions and the

alkali nutrient ion ingredient solutions from the acid solution tank means and

the alkali solution tank means are controlled in order to bring said at least

one of the ion concentrations to the prescribed acceptable range.

6. The

system of claim 1, further comprising:

electrolytic conductivity meter

means for measuring electrolytic conductivity of the nutrient solution in the

nutrient solution tank means;

high concentration nutrient solution tank

means for containing high concentration nutrient solutions to be supplied to the

nutrient solution in the nutrient solution tank means; and

water supply

means for supplying water to be supplied to the nutrient solution in the

nutrient solution tank means;

and wherein the controlling means also

controls the supplies of the high concentration nutrient solutions and the water

from the high concentration nutrient solution tank means and the water supply

means according to the electrolytic conductivity measured by the electrolytic

conductivity meter means.

7. The system of claim 6, wherein the

controlling means also controls the supplies of the acid nutrient ion ingredient

solutions, the alkali nutrient ion ingredient solutions, and the water from the

acid solution tank means, the alkali solution tank means, and the water supply

means, such that when the ion concentrations for at least one nutrient ion

ingredient measured by the ion analyzer means is higher than the prescribed

acceptable range, those alkali nutrient ion ingredient solutions and those acid

nutrient ion ingredient solutions which do not contain said at least one

nutrient ion ingredient are supplied from the alkali solution tank means and the

acid solution tank means until the ion concentrations for all the nutrient ion

ingredients are balanced, and then the water is supplied from the water supply

means until the electrolytic conductivity of the nutrient solution in the

nutrient solution tank means is restored to that before the supplies of the acid

nutrient ion ingredient solutions and the alkali nutrient ion ingredient

solutions from the acid solution tank means and the alkali solution tank means.

8. The system of claim 7, wherein the controlling means controls the pH

of the nutrient solution in the nutrient solution tank means again after the

supplies of the acid nutrient ion ingredient solutions, the alkali nutrient ion

ingredient solutions, and the water from the acid solution tank means, the

alkali solution tank means, and the water supply means are controlled in order

to bring said at least one of the ion concentrations to the prescribed

acceptable range.

9. A hydroponic nutrient solution control system for

continuous controlling the individual nutrient ion content of a nutrient

solution to be supplied to plants to be grown, comprising:

nutrient

solution tank means for containing the nutrient solution to be supplied to the

plants, to which the nutrient solution supplied to the plants are returned;

pH meter means for measuring pH of the nutrient solution in the nutrient

solution tank means;

an ion analyzer device for measuring an ion

concentration of a plurality of nutrient ion ingredients of the nutrient

solution in the nutrient solution tank means independent of other nutrient ion

ingredients of the nutrient solution in the nutrient solution tank means;

a plurality of acid solution tank means for containing acid nutrient ion

ingredient solutions, each acid solution tank means separately containing an

acid nutrient ion ingredient solution comprising a compound selected from the

group consisting of HNO.sub.3, H.sub.3 PO.sub.4, and H.sub.2 SO.sub.4, to be

supplied to the nutrient solution in the nutrient solution tank means, wherein

each acid nutrient ion ingredient solution is capable of both lowering the

effective pH of the nutrient solution and raising the concentration of a single

nutrient ion contained in the nutrient solution;

a plurality of alkali

solution tank means for containing alkali nutrient ion ingredient solutions,

each alkali solution tank means separately containing an alkali nutrient ion

ingredient solution comprising a compound selected from the group consisting of

KOH, Ca(OH).sub.2, Mg(OH).sub.2, and NH.sub.4 OH, to be supplied to the nutrient

solution in the nutrient solution tank means, wherein each alkali nutrient ion

ingredient solution is capable of both raising the effective pH of the nutrient

solution and raising the concentration of a single specific nutrient ion

contained in the nutrient solution; and

means for automatically

controlling supplies of the acid nutrient ion ingredient solutions and the

alkali nutrient ion ingredient solutions by selectively operating appropriate

ones of the acid solution tank means and alkali solution tank means, according

to the pH measured by the pH meter means and the ion concentrations measured by

the ion analyzer device.

Description

BACKGROUND OF THE INVENTION

1. Field of the Invention

The present invention relates to a hydroponic nutrient solution control

system for growing plants hydroponically by controlling supplies of nutrient

solutions (solutions of inorganic fertilizers in water) to the plants.

2. Description of the Background Art

In the hydroponics, the

plants are grown under the control of a hydroponic nutrient solution control

system which controls supplies of nutrient solutions to the plants.

In a

conventional hydroponic nutrient solution control system, this controlling is

performed according to the pH and/or the electrolytic conductivity of the

nutrient solutions.

For instance, when the electrolytic conductivity of

the nutrient solution decreased, high concentration nutrient solutions are

supplied to the nutrient solution in order to raise the electrolytic

conductivity to prescribed target range, whereas when the electrolytic

conductivity of the nutrient solution increased, water is added to the nutrient

solution in order to lower the electrolytic conductivity to prescribed target

range.

Similarly, in a case of using the pH, an acid solution and an

alkali solution are used to control the pH of the nutrient solution within a

prescribed target range.

However, in such a conventional hydroponic

nutrient solution control system, it has been difficult to accurately supply the

nutrient solutions containing the ingredients necessary for the plants to be

grown. This is due to the fact that in a course of the growth of the plants, the

organic acids are leaked from the roots of the plants, such that even when the

ingredients unnecessary for the plants are being compiled, this fact is not

reflected by the pH or the electrolytic conductivity of the nutrient solutions.

As a consequence, the necessary adjustments of the nutrient solutions cannot be

provided, so that the growth of the plants are retarded if not hampered fatally.

Also, because the information on the pH and the electrolytic

conductivity cannot reflect the actual state of the nutrient solutions

accurately, even when the abnormality was found in the growing plants, the cause

of the abnormality cannot be ascertained from the information on the pH and the

electrolytic conductivity, so that the entire nutrient solutions have to be

replaced in such a case, which increases the waste of the nutrient solutions.

Also, in a conventional hydroponic nutrient solution control system, the

controlling of the pH is performed by using one acid solution and one alkali

solution only. However, necessary amounts of the acid solution or the alkali

solution vary from time to time, so that it is desirable to have more than one

acid solutions and more than one alkali solutions, in order to be able to cope

with various different situations.

It is known that a plant in a process

of growing may consume particular ingredients more than other ingredients,

depending on the external conditions such as an amount of sunshine, a

temperature of the air, and a temperature of the nutrient solution. In such a

case, the nutrient solution control according to the pH or the electrolytic

conductivity tends to cause a lack of particular nutrient solution ion

ingredients. In this state, the plant is unable to absorb the necessary ion

ingredients because of their low concentration in the nutrient solution.

On the other hand, the ion ingredients in the nutrient solution cannot

be controlled easily, because the ions exist in forms of bases such as

KNO.sub.3.

Furthermore, when the concentration of a particular kind of

ions is very low, the balance of ions achieved in the original nutrient solution

is often lost, such that the pH of the nutrient solution often differs greatly

from the original value.

SUMMARY OF THE INVENTION

It is

therefore an object of the present invention to provide a hydroponic nutrient

solution control system capable of performing the nutrient solution control

automatically, accurately, effectively, and efficiently.

According to

one aspect of the present invention there is provided a hydroponic nutrient

solution control system for controlling nutrient solution to be supplied to

plants to be grown, comprising: nutrient solution tank means for containing the

nutrient solution to be supplied to the plants, to which the nutrient solution

supplied to the plants are returned; pH meter means for measuring pH of the

nutrient solution in the nutrient solution tank means; ion analyzer means for

measuring ion concentrations of nutrient ion ingredients of the nutrient

solution in the nutrient solution tank means; acid solution tank means for

containing acid nutrient ion ingredient solutions to be supplied to the nutrient

solution in the nutrient solution tank means; alkali solution tank means for

containing alkali nutrient ion ingredient solutions to be supplied to the

nutrient solution in the nutrient solution tank means; and means for controlling

supplies of the acid nutrient ion ingredient solutions and the alkali nutrient

ion ingredient solutions from the acid solution tank means and the alkali

solution tank means, according to the pH measured by the pH meter means and the

ion concentrations measured by the ion analyzer means.

According to

another aspect of the present invention there is provided a method of hydroponic

nutrient solution control for controlling nutrient solution to be supplied to

plants to be grown, comprising the steps of: providing nutrient solution tank

means for containing the nutrient solution to be supplied to the plants, to

which the nutrient solution supplied to the plants are returned; measuring pH of

the nutrient solution in the nutrient solution tank means by pH meter means;

measuring ion concentrations of nutrient ion ingredients of the nutrient

solution in the nutrient solution tank means by ion analyzer means; providing

acid solution tank means for containing acid nutrient ion ingredient solutions

to be supplied to the nutrient solution in the nutrient solution tank means;

providing alkali solution tank means for containing alkali nutrient ion

ingredient solutions to be supplied to the nutrient solution in the nutrient

solution tank means; and controlling supplies of the acid nutrient ion

ingredient solutions and the alkali nutrient ion ingredient solutions from the

acid solution tank means and the alkali solution tank means, according to the pH

measured by the pH meter means and the ion concentrations measured by the ion

analyzer means.

Other features and advantages of the present invention

will become apparent from the following description taken in conjunction with

the accompanying drawings.

BRIEF DESCRIPTION OF THE DRAWINGS

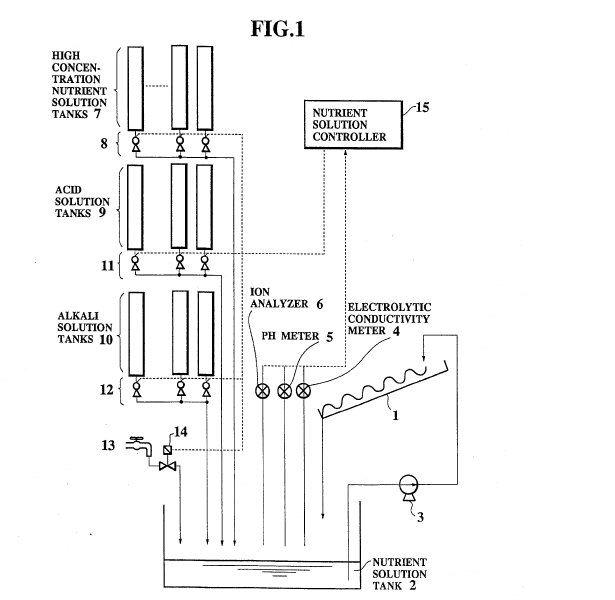

FIG. 1 is a block diagram of one embodiment of a hydroponic nutrient

solution control system according to the present invention.

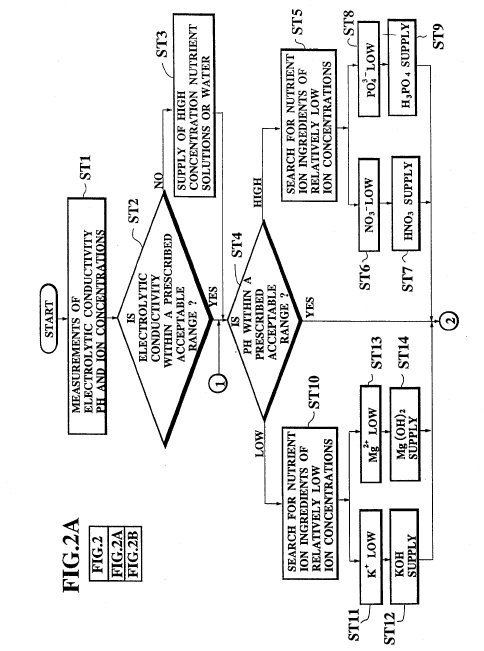

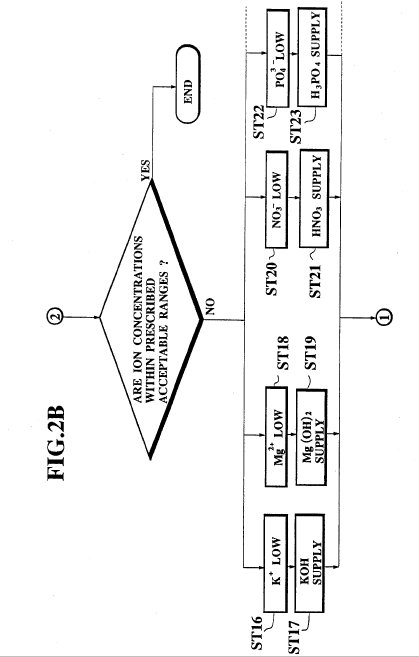

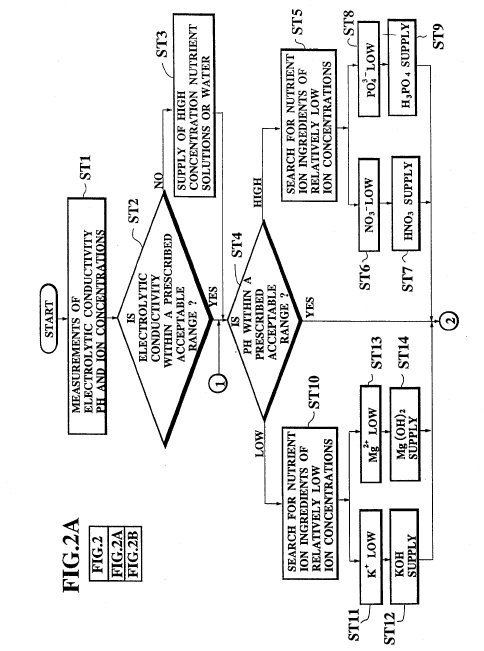

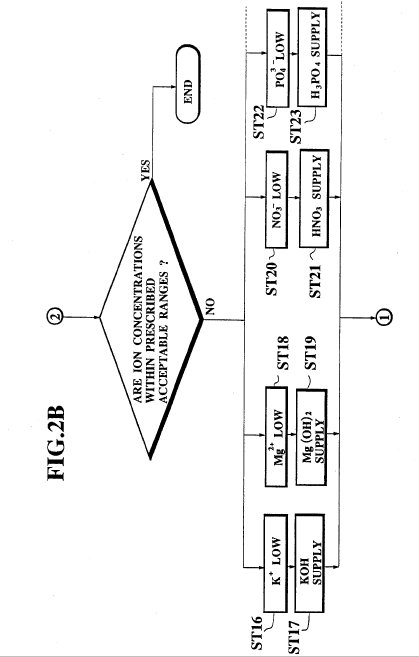

FIG. 2 which

has been divided into two parts (FIG. 2A and FIG. 2B) is a flow chart for the

nutrient solution control operation performed by the system of FIG. 1.

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

Referring now

to FIG. 1, one embodiment of a hydroponic nutrient solution control system

according to the present invention will be described in detail.

This

system is adapted to a so called NFT (nutrient flow technique) culture method,

and comprises a culture panel 1 on which plants to be grown are planted, a

nutrient solution tank 2 for containing the nutrient solution to be supplied to

the plants, and a supply pump 3 for supplying the nutrient solution in the

nutrient solution tank 2 to an upper stream side of the culture panel 1 from

which the nutrient solution flows down through a lower stream side of the

culture panel 1 back to the nutrient solution tank 2 while supplying the

nutrient ingredients to the plants.

The system further comprises an

electrolytic conductivity meter 4 for measuring an electrolytic conductivity of

the nutrient solution in the nutrient solution tank 2 which is proportional to a

concentration of the nutrient solution and therefore is indicative of the total

ion concentration of the nutrient solution as a whole, a pH meter 5 for

measuring a balance of acid and alkali, i.e., pH of the nutrient solution in the

nutrient solution tank 2, and an ion analyzer 6 for analyzing ion contents and

measuring ion concentrations of the nutrient solution in the nutrient solution

tank 2. The multi-ion meter LQ201 of Toshiba which uses the ion electrode method

is suitable for the ion analyzer 6 of this system.

The system further

comprises a plurality of high concentration nutrient solution tanks 7 for

containing several high concentration nutrient solutions to be supplied to the

nutrient solution tank 2, a plurality of high concentration nutrient solution

tank pumps 8 capable of controlling amounts of the high concentration nutrient

solutions flowing out from the high concentration nutrient solution tanks 7, a

plurality of acid solution tanks 9 and a plurality of alkali solution tanks 10

for containing several acid ingredient solutions and several alkali ingredient

solutions, respectively, to be supplied to the nutrient solution tank 2, a

plurality of acid solution tank pumps 11 and a plurality of alkali solution tank

pumps 12 capable of controlling amounts of the acid ingredient solutions and the

alkali ingredient solutions flowing out from the acid solution tank 9 and the

alkali solution tank 10, respectively, a water supply 13 for supplying water to

dilute the nutrient solution in the nutrient solution tank 2, a water supply

electromagnetic valve 13 capable of controlling an amount of water flowing out

from the water supply 13, and a nutrient solution controller 15 for controlling

the high concentration nutrient solution tank pumps 8, acid solution tank pumps

11, alkali solution tank pumps 12, and a water supply electromagnetic valve 14,

according to the electrolytic conductivity, pH, and ion concentrations of ion

contents obtained by the electrolytic conductivity meter 4, pH meter 5, and ion

analyzer 6.

The high concentration nutrient solution tanks 7 separately

contain various high concentration nutrient solutions which includes various

nutrient ingredient ions at high concentrations.

The acid solution tanks

9 separately contain various acid nutrient ion ingredient solutions including

those of the major nutrient ion ingredients such as HNO.sub.3, H.sub.3 PO.sub.4,

and H.sub.2 SO.sub.4, as well as those of minor nutrient ion ingredients such as

H.sub.3 BO.sub.4 and H.sub.2 MoO.sub.4.

The alkali solution tanks 10

separately contain various alkali nutrient ion ingredient solutions including

those of the major nutrient ion ingredients such as KOH, Ca(OH).sub.2,

Mg(OH).sub.2 and NH.sub.4 OH, as well as those of minor nutrient ion ingredients

such as Fe(OH).sub.2, Fe(OH).sub.3, Mn(OH).sub.2, Zn(OH).sub.2, and

Cu(OH).sub.2.

This system operates under the control of the nutrient

solution controller 15 according to the flow chart of FIG. 2, as follows.

Initially, in preparing new nutrient solution, the high concentration

nutrient solution tank pumps 8 and the water supply electromagnetic valve 14 are

controlled according to the growth level of the plants to be grown, so as to

fill the nutrient solution tank 2 with the appropriate nutrient solution

containing all the nutrient ion ingredients necessary for the plants mixed

evenly.

As the supply pump 3 supplies this nutrient solution in the

nutrient solution tank 2 to the upper stream side of the culture panel 1 from

which the nutrient solution flows down through the lower stream side of the

culture panel 1 back to the nutrient solution tank 2 while supplying the

nutrient ion ingredients to the plants, those nutrient ion ingredients which are

easier to be absorbed decrease, and the pH of the nutrient solution changes.

In order to control such a situation, first at the step ST1, the

nutrient solution controller 15 collects the electrolytic conductivity, pH, and

ion concentrations of ion contents of the nutrient solution in the nutrient

solution tank 2 measured by the electrolytic conductivity meter 4, pH meter 5,

and ion analyzer 6 through regular constant interval samplings.

Next, at

the step ST2, whether the measured electrolytic conductivity is within a

prescribed acceptable range or not is determined. When the measured electrolytic

conductivity is found to be within the prescribed acceptable range, the step ST4

will be taken next. Otherwise, next at the step ST3, when the measured

electrolytic conductivity is found to be too low, the high concentration

nutrient solution tank pumps 8 are controlled such that appropriate amounts of

the high concentration nutrient solutions to raise the electrolytic conductivity

of the nutrient solution up to the prescribed acceptable range are supplied to

the nutrient solution tank 2, whereas when the measured electrolytic

conductivity is found to be too high, the water supply electromagnetic valve 14

is controlled such that appropriate amount of the water to lower the

electrolytic conductivity of the nutrient solution up to the prescribed

acceptable range is supplied to the nutrient solution tank 2.

Then at

the step ST4, whether the measured pH is within a prescribed acceptable range or

not is determined. When the measured pH is found to be within the prescribed

acceptable range, the step ST15 will be taken next.

Otherwise, when the

measured pH is found to be too high, i.e., when the nutrient solution is

excessively alkalic, those nutrient ion ingredients whose ion concentrations are

found to be relatively low are supplied from the acid solution tanks 9 in forms

of acid ingredient solutions by controlling the acid solution tank pumps 11, so

as to bring the pH of the nutrient solution to the prescribed acceptable range.

Namely, in this case, next at the step ST5, the ion concentrations of the ion

contents of the nutrient solution are checked to find those nutrient ion

ingredients whose ion concentrations are found to be relatively low. Then, when

the ion concentration for NO.sub.3 - is found to be relatively low (a case of

step ST6) for example, an appropriate amount of the HNO.sub.3 solution is

supplied at the step ST7, whereas when the ion concentration for PO.sub.4.sup.3-

is found to be relatively low (a case of step ST8) for example, an appropriate

amount of the H.sub.3 PO.sub.4 solution is supplied at the step ST9.

On

the other hand, when the measured pH is found to be too low, i.e., when the

nutrient solution is excessively acidic, those nutrient ion ingredients whose

ion concentrations are found to be relatively low are supplied from the alkali

solution tanks 10 in forms of alkali ingredient solutions by controlling the

alkali solution tank pumps 12, so as to bring the pH of the nutrient solution to

the prescribed acceptable range. Namely, in this case, next at the step ST10,

the ion concentrations of the ion contents of the nutrient solution are checked

to find those nutrient ion ingredients whose ion concentrations are found to be

relatively low. Then, when the ion concentration for K.sup.+ is found to be

relatively low (a case of step ST11) for example, an appropriate amount of the

KOH solution is supplied at the step ST12, whereas when the ion concentration

for Mg.sup.2+ is found to be relatively low (a case of step ST13) for example,

an appropriate amount of the Mg(OH).sub.2 solution is supplied at the step ST14.

Then, at the step ST15, the ion concentrations of the ion contents of

the nutrient solution are checked to find those nutrient ion ingredients whose

ion concentrations are found to be lower than prescribed acceptable ranges. This

step is taken because the ion concentrations for all the nutrient ion

ingredients of the nutrient solution may not necessarily be within the

prescribed acceptable ranges, even when the pH of the nutrient solution is

within the prescribed acceptable range. Thus, when the ion concentrations for

all the nutrient ion ingredients of the nutrient solution are found to be within

prescribed acceptable ranges, the controlling process by the nutrient solution

controller 15 is terminated until the next samplings of the electrolytic

conductivity, pH and ion concentrations.

Otherwise, when the ion

concentration for positive ions such as K.sup.+ or Mg.sup.2+ is found to be

lower than the prescribed acceptable range (a case of step ST16 or ST18) for

example, an appropriate amount of the KOH solution or Mg(OH).sub.2 solution is

supplied at the step ST17 or ST19, respectively, whereas when the ion

concentration for negative ions such as NO.sub.3.sup.- or PO.sub.4.sup.3- is

found to be lower than the prescribed acceptable range (a case of step ST20 or

ST22) for example, an appropriate amount of the HNO.sub.3 solution or H.sub.3

PO.sub.4 solution is supplied at the step ST21 or ST23, respectively, so as to

bring ion concentrations for all the nutrient ion ingredients of the nutrient

solution to the prescribed acceptable ranges.

In a case the ion

concentrations for certain nutrient ion ingredients are found to be higher than

the prescribed acceptable ranges at the step ST15, the supply from the acid

solution tanks 9 or the alkali solution tanks 10 which contain solutions of such

nutrient ion ingredients are stopped while the supply from all the other acid

solution tanks 9 and the alkali solution tanks 10 are continued so as to achieve

the overall balance for the ion concentrations for all the nutrient ion

ingredients of the nutrient solution, and then the entire nutrient solution is

diluted by the water from the water supply 13 in order to restore the original

overall ion concentration of the nutrient solution as a whole.

Then, the

process returns to the step ST4 described above, so as to check the pH of the

nutrient solution once again, because the pit may be changed as a result of the

ion concentration control at the steps ST16 to ST23.

Thus, according to

this system, not only the electrolytic conductivity and pH, but also the ion

concentrations for the nutrient ion ingredients of the nutrient solution are

controlled, so that the nutrient solution control can be performed more

accurately and effectively.

Also, according to this system, the pH of

the nutrient solution is controlled according to the ion concentrations for the

nutrient ion ingredients of the nutrient solution, so that the overuse and waste

of the acid or alkali solutions for the purpose of pH controlling can be

prevented, and therefore the nutrient solution control can be performed more

efficiently and stably.

Furthermore, the entire nutrient solution

control can be performed under the controlling by the nutrient solution

controller 15 which can be adapted to different types of plants to be grown,

different conditions in which the plants are to be grown, or different growth

levels of the plants to be grown, by the appropriate programming according to

the most suitable nutrient solution for a given situation, so that the entire

nutrient solution control can be performed automatically.

It is to be

noted that, although the above embodiment has been described for the system

adapted to the NFT culture method, it should be obvious that the present

invention is equally applicable to the system for the other culture method such

as a rock wool culture method and a DFT (deep flow technique) culture method.

Besides this, many modifications and variations of the above embodiments

may be made without departing from the novel and advantageous features of the

present invention. Accordingly, all such modifications and variations are

intended to be included within the scope of the appended claims.

* * * * *

![[US Patent & Trademark Office, Patent Full Text and Image Database]](United States Patent 5,598,663.files/patfthdr.gif)

![[Home]](United States Patent 5,598,663.files/home.gif)

![[Boolean Search]](United States Patent 5,598,663.files/boolean.gif)

![[Manual Search]](United States Patent 5,598,663.files/manual.gif)

![[Number Search]](United States Patent 5,598,663.files/number.gif)

![[Help]](United States Patent 5,598,663.files/help.gif)

![[HIT_LIST]](United States Patent 5,598,663.files/hitlist.gif)

![[PREV_DOC]](United States Patent 5,598,663.files/prevdoc.gif)

![[NEXT_DOC]](United States Patent 5,598,663.files/nextdoc.gif)

![[Bottom]](United States Patent 5,598,663.files/bottom.gif)

![[View Shopping Cart]](United States Patent 5,598,663.files/cart.gif)

![[Add to Shopping Cart]](United States Patent 5,598,663.files/order.gif)

![[Image]](United States Patent 5,598,663.files/image.gif)

![[US Patent & Trademark Office, Patent Full Text and Image Database]](United States Patent 5,598,663.files/patfthdr.gif)

![[Home]](United States Patent 5,598,663.files/home.gif)

![[Boolean Search]](United States Patent 5,598,663.files/boolean.gif)

![[Manual Search]](United States Patent 5,598,663.files/manual.gif)

![[Number Search]](United States Patent 5,598,663.files/number.gif)

![[Help]](United States Patent 5,598,663.files/help.gif)

![[HIT_LIST]](United States Patent 5,598,663.files/hitlist.gif)

![[PREV_DOC]](United States Patent 5,598,663.files/prevdoc.gif)

![[NEXT_DOC]](United States Patent 5,598,663.files/nextdoc.gif)

![[Bottom]](United States Patent 5,598,663.files/bottom.gif)

![[View Shopping Cart]](United States Patent 5,598,663.files/cart.gif)

![[Add to Shopping Cart]](United States Patent 5,598,663.files/order.gif)

![[Image]](United States Patent 5,598,663.files/image.gif)