![[US Patent & Trademark Office, Patent Full Text and Image Database]](United States Patent 5,858,202.files/patfthdr.gif)

| United States Patent |

5,858,202 |

| Nakamura |

January 12, 1999 |

Method for producing electrolytic water and apparatus for

producing the same

Abstract

The invention provides a method and apparatus for producing an electrolytic

water whereby one electrolytic water used in compliance with its intended use is

transformed into a water more effectively used and the by-product electrolytic

water, previously disposed as virtually useless, is transformed into a water

which can be effectively used by use of at least two electrolyzer in series. At

least one of an outlet for a primary anodic electrolytic water in a primary

electrolyzer and an outlet for a primary cathodic electrolytic water in a

primary electrolyzer is connected to an inlet of a secondary electrolyzer

through a first switching valve and a second switching valve. The anodic

electrolytic water only, the primary cathodic electrolytic water only, or

mixture of the primary anodic and primary cathodic electrolytic water is fed to

the secondary electrolyzer to be electrolyzed again. A chlorine remover is

provided within the secondary inlet for connecting the primary electrolyzer with

the secondary electrolyzer and it removes chlorine from a primary electrolytic

water, and afterward, the filtered water is electrolyzed again in the secondary

electrolyzer. Tertiary electrolysis of the secondary anodic electrolytic water,

produced by electrolysis of the primary anodic electrolytic water, will produce

a tertiary anodic electrolytic water that exhibits a remarkably high

bactericidal effect.

| Inventors: |

Nakamura; Tadamasa (Tokyo, JP) |

| Assignee: |

Zenkoku-Mokko-Kikai-Kan, Inc. (JP)

|

| Appl. No.: |

788196 |

| Filed: |

January 24, 1997 |

Foreign Application Priority Data

|

Jan 30, 1996[JP] |

8-014534 |

| Current U.S. Class: |

205/746; 204/257; 204/278.5

|

| Intern'l Class: |

C02F 001/461 |

| Field of Search: |

205/746,770 204/257,275

|

References Cited [Referenced

By]

U.S. Patent Documents

Primary

Examiner: Phasge; Arun S.

Attorney, Agent or Firm: Lorusso &

Loud

Claims

What is claimed is:

1. An apparatus for producing an

electrolytic water, said apparatus comprising:

a primary electrolyzer

including a primary anode and a primary cathode and a separating membrane

dividing the interior of the primary electrolyzer into a primary anode

compartment containing the primary anode and a cathode compartment containing

the primary cathode;

a secondary electrolyzer including a secondary

anode and a secondary cathode and a separating membrane dividing the secondary

electrolyzer into a secondary anode compartment containing the secondary anode

and a secondary cathode compartment containing the secondary cathode;

a

first primary outlet for primary anodic water connected to the primary anode

compartment;

a first switching valve connected to the first primary

outlet;

a second primary outlet for primary cathodic water connected to

the primary cathode compartment;

a second switching valve connected to

the second primary outlet;

a combined primary outlet passage for

connecting the first switching valve with the second switching valve;

a

secondary inlet connecting the combined primary outlet with the secondary

electrolyzer;

a first secondary outlet for secondary anodic water

connected to the secondary anode compartment;

a second secondary outlet

for secondary cathodic water connected to the secondary cathode compartment; and

a chlorine remover provided in the secondary inlet, between the primary

electrolyzer and the secondary electrolyzer.

2. An apparatus for

producing an electrolytic water as claimed in claim 1, additionally comprising:

a third switching valve upstream of the chlorine remover in the

secondary inlet; and

a bypass connecting the third switching valve with

the secondary inlet at a point downstream of the chlorine remover, whereby water

may be passed either through the chlorine remover or through the bypass by

switching the third switching valve.

3. An apparatus for producing an

electrolytic water as claimed in claim 1, further comprising:

a

secondary anodic water switching valve in the first secondary outlet; and

an anodic water communication passage connecting the secondary anodic

water switching valve with the first switching valve;

whereby the

primary anodic water passing through the first switching valve from the first

primary outlet and the secondary anodic water passing through the secondary

anodic water switching valve from the first secondary outlet may be mixed in the

anodic water communication passage and removed together through the first

primary outlet.

4. An apparatus for producing an electrolytic water as

claimed in claim 1, further comprising:

a secondary cathodic water

switching valve in the second secondary outlet; and

a cathodic water

communication passage connecting the secondary cathodic water switching valve

with the second switching valve;

whereby cathodic water passing through

the second switching valve from the second primary outlet and the cathodic water

passing through the secondary cathodic water switching valve from the second

secondary outlet are mixed in the cathodic water communication passage and

removed together through the second primary outlet.

5. A method for

producing electrolytic water product comprising:

feeding a raw water to

a primary electrolyzer having an interior divided into a primary anode

compartment containing an anode and a primary cathode compartment containing a

cathode;

electrolyzing the raw water within the primary electrolyzer to

produce a primary anodic water and a primary cathodic water;

removing

chlorine by passing at least one said primary anodic water and said primary

cathodic water through a chlorine filter to produce a chlorine free water;

feeding the chlorine free water to a secondary electrolyzer having an

interior divided into a secondary anode compartment containing an anode and a

secondary cathode compartment containing a cathode; and

electrolyzing

the chlorine free water within the secondary electrolyzer to produce a secondary

anodic water and a secondary cathodic water.

6. A method for producing

an electrolytic water as claimed in claim 5, wherein the primary anodic water

only is passed through the chlorine filter and electrolyzed in the secondary

electrolyzer.

7. A method for producing an electrolytic water as claimed

in claim 5, further comprising:

feeding at least one of the secondary

anodic water and the secondary cathodic water to a tertiary electrolyzer having

an interior divided into a tertiary anode compartment containing an anode and a

tertiary cathode compartment containing a cathode; and

electrolyzing the

feed to the tertiary electrolyzer to produce a tertiary anodic water and a

tertiary cathodic water.

8. A method for producing an electrolytic water

as claimed in claim 5 wherein the primary cathodic water only is passed through

the chlorine filter and electrolyzed in the secondary electrolyzer.

9. A

method for producing an electrolytic water as claimed in claim 5 wherein a

mixture of the primary anodic water and the primary cathodic water is passed

through the chlorine filter and then electrolyzed in the secondary electrolyzer.

Description

BACKGROUND OF THE INVENTION

1. Field of the Invention

The present invention relates to a method for producing an electrolytic

water whereby the effectiveness of one conventional type of electrolytic water

is enhanced and the other type of electrolytic water, conventionally disposed of

as virtually useless, is transformed into an electrolytic water which can be

effectively used, and to an apparatus for producing the same.

2.

Description of the Related Art

An electrolytic water producer has been

known which produces an electrolytic acid water and electrolytic alkaline water

by electrolyzing water. The main components of the electrolytic water producer

are an electrolyzer and a power supply. The inside of the electrolyzer is

divided into two areas by a separating membrane, in one area of which a positive

electrode is disposed, and in the other area of which a negative electrode is

disposed. Applying a current across both of the electrodes in the electrolyzer

filled with water produces the electrolytic acid water in the area where the

positive electrode is disposed and the electrolytic alkaline water in the area

where the negative electrode is disposed.

The electrolytic alkaline

water is recognized to be effective for depressing an abnormal intestinal

fermentation and is used for a drinking water. The electrolytic acid water is

acknowledged to be effective in bactericidal and astringent actions, and is used

for cleaning and medical treatment. Thus, each type of electrolytic water has

widely been used for enhancing health.

In evaluation of the electrolytic

water, the pH value representing hydrogen ion concentration and the residual

chlorine concentration have been conventionally used. However, as use of

electrolytic water producers has become widespread, even without any significant

differences in the pH value or in the residual chlorine concentration of the

electrolytic water, differences in electrolytic water effectiveness are noted as

dependent on apparatus and region of use.

In the electrolytic alkaline

water, when the oxidation reduction potential and dissolved oxygen concentration

are low, the water usually displays a high effectiveness for improving health;

whereas when the oxidation reduction potential and dissolved oxygen

concentration are comparably high, the water shows a low effectiveness for

improving health in most cases. A low oxidation reduction potential was

considered -50-250 mv, a low dissolved oxygen concentration was considered

4.8-6.8 mg/l, a high oxidation reduction potential was considered +100-+250 mv

and a high dissolved oxygen concentration was considered 7-8.2 mg/l.

Accordingly, using an identical service water as the raw water,

selecting a model A to produce an electrolytic water with a low oxidation

reduction potential and a given pH value, and a model B to produce an

electrolytic water with a comparably higher oxidation reduction potential and an

identical pH value, a comparison test using rats was made simultaneously with

the service water, the electrolytic water produced by the model A, and the

electrolytic water produced by the model B by a single testing organization. The

test results showed an influence on the gastric mucosal damage, i.e. that the

area of erosion on a gastric mucosa tends to become smaller in the following

order: electrolytic water produced by the model A, electrolytic water produced

by the model B, and service water. A survival test using cancer transplanted

immunodefficient mice was made by another testing organization in a similar

manner, and the test confirmed a similar tendency in the survival rate.

The oxidation reduction potential and dissolved oxygen concentration of

the waters used in these tests were on average: +230 mv, 8.2 mg/l for the

service water; -150 mv, 6.2 mg/l for the electrolytic alkaline water produced by

the model A; and +75 mv, 7.6 mg/l for the electrolytic alkaline water produced

by the model B.

Another test on the survival rate using critical

immunodefficient mice made by another organization employed: the service water

with a pH of 7.6, an oxidation reduction potential of +520 mv, and a dissolved

oxygen concentration of 78 mg/l; a first electrolytic alkaline water C

(hereinafter "water C") with a pH of 10.4, an oxidation reduction potential of

-485 mv, and a dissolved oxygen concentration of 5.8 mg/l; and a second

electrolytic alkaline water D (hereinafter "water D") with a pH of 8.9, an

oxidation reduction potential of -309 mv, and a dissolved oxygen concentration

of 7.22 mg/l. The test results reported for the survival rate with the service

water group, water C group, and water D group were 20.9%, 56.0%, 44.0%,

respectively.

According to the aforementioned test results, in the

electrolytic alkaline water, as the oxidation reduction potential and dissolved

oxygen concentration become lower, the effectiveness becomes higher, indicating

need for an apparatus which produces an electrolytic alkaline water with a low

oxidation reduction potential and dissolved oxygen concentration, without being

subject to influence by the state of the raw water.

The electrolytic

acid water, produced as a waste water in producing the electrolytic alkaline

water for drinking, is considered to have an astringent action and a

bactericidal action. However, its effectiveness is not so apparent as to be

really recognized in most cases, and most of such acidic waters are disposed as

waste.

When the pH decreases to about 4, the oxidation reduction

potential becomes more than +800 mv, and the dissolved oxygen concentration

becomes more than 10 mg/l, the electrolytic acid water clearly displays the

astringent action when applied to the skin and makes the skin smooth after the

water dries. The electrolytic acid water gives the smooth feeling to the skin

stronger and longer, as the pH value becomes lower, the oxidation reduction

potential becomes higher, and the dissolved oxygen concentration becomes higher.

The bacteriostatic effect also has a similar tendency. For example, if the pH

value is less than 3.5, the oxidation reduction potential is more than +900 mv,

and the dissolved oxygen concentration is more than 12 mg/l, the electrolytic

acid water will exhibit such a strong bactericidal activity as to kill most

bacteria in a short time even with a dissolved chlorine concentration of about 2

ppm, indicating possible utility as an effective antibacterial agent that does

not damage the skin or mocosa.

However, the conventional apparatus can

not stably produce an effective acid electrolytic water, because the water

quality of the raw water, e.g. service water, changes significantly with the

seasons, with temperature, and with time. Furthermore, the conventional

apparatus required such maintenance control that an electrolyte solution of a

specific concentration always has to be kept so as not to be out of stock.

The raw water fed to the electrolytic water producer sometimes contains

free chlorine as hypochlorite, iron rust, and turbidity. In such a case, it is a

common practice to pass the raw water through a chlorine remover having a filter

for rejecting chlorine of an activated carbon alone or a combination of an

activated carbon, hollow fiber membranes and calcium sulfites, and afterward to

feed the raw water into the electrolytic water producer. Furthermore, where the

major objective is producing an electrolytic water with bactericidal activity,

it is also a common practice to add chlorides such as a sodium chloride and/or

potassium chloride to the raw water as electrolytes.

There are various

types of such apparatus: one type employing a constant current power supply as

the power supply to the electrodes in order to stabilize electrolysis; apparatus

capable of switching the ranges of a current from a constant current power

supply; and apparatus with a pH controller that measures the electric

conductivity of an electrolytic water and feeds back the measured result to the

electrolyzing power supply.

In the case of the apparatus capable of

producing the electrolytic alkaline water for drinking such that the pH value

does not exceed 11, the oxidation reduction potential will vary in the range

from +150 mv to -250 mv and will be unstable, depending on the potential of the

raw water, the gas dissolved in the raw water, the electrolytes contained in the

raw water, and the quantity of water treated.

In case of the apparatus

provided with the pH controller, it is possible to produce an electrolytic water

with a comparably stable pH value; however, the oxidation reduction potential

changes significantly, depending on differences in the raw water as in the

previous case.

When chlorides are added as electrolytes, it is possible

to produce an electrolytic acid water with a low pH value and a high oxidation

reduction potential; however, this technique is prone to a high free dissolved

chlorine concentration of more than 50-150 ppm and it has proven very difficult

to reliably suppress the flee dissolved chlorine concentration to less than a

specific limit.

On the other hand, the electrolytic acid water

containing free chlorine has a bactericidal effect. For instance, in the

treatment of atopic dermatitis with a serious secondary infection, a high

chlorine concentration displays a significant effect of skin disinfection. The

free dissolved chlorine concentration contained in an electrolytic acid water

does not damage a healthy skin up to about 50 ppm; however, if the electrolytic

acid water is repeatedly applied several times a day to a skin that is chapped

or inflamed or anaphylactic, the electrolytic acid water with a chlorine

concentration of more than 25 ppm reportedly causes a slight damage such as

eruption owing to irritation. Therefore, the chlorine concentration should be

controlled to less than 20 ppm for safety, except for use under supervision of a

doctor.

Furthermore, electrolytic alkaline water coproduced with

electrolytic acid water having a strong bactericidal effect will sometimes have

a high pH value exceeding pH 11 and a low oxidation reduction potential of less

than -800 mv. Such an electrolytic alkaline water is rich in metal ions such as

sodium and potassium ions derived from electrolytes, and drinking such an

electrolytic alkaline water is a danger to one's physical condition and it is

very bad tasting. Accordingly, such alkaline water has been disposed as waste,

although it can be used for cleaning utensils and the like.

Generally,

the quantity of added electrolytes is in the range of 500.+-.200 mg/l as sodium

chloride. In the case of chlorine ions as electrolytes contained in the service

water as a raw water, the maximum level of chlorine ion content consistent with

water quality standards is 200 mg/l (329 mg/l as NaCl). Accordingly, in the

electrolyte addition type apparatus also, the quality of the raw water specially

significantly influences the oxidation reduction potential and free dissolved

chlorine concentration of the electrolytic water thereby produced.

In

the conventional apparatus, the electrolysis is conducted in one electrolyzer;

and for a raw water of constant quality, the quantity of water to be treated and

the amount of current to be applied will determine a quantitative combination of

a pH value, oxidation reduction potential, dissolved oxygen concentration, free

dissolved chlorine concentration, electric conductivity, and the like.

Consequently, it was difficult to simultaneously produce an electrolytic water

with a different quantitative combination of these and also difficult to produce

an electrolytic alkaline water suitable for drinking and an electrolytic acid

water with a bactericidal and bacteriostatic effect.

Furthermore, the

conventional apparatus is designed without paying attention to the function of

dissolved oxygen and, in fact, the dissolved oxygen concentration of the

electrolytic water is completely disregarded.

SUMMARY OF THE INVENTION

The present invention has been made in view of the foregoing problems,

and an object of the present invention is to provide a method for producing an

acidic or alkaline type electrolytic water which can be more effectively used by

repeating electrolysis more than two times and the other type electrolytic

water, conventionally disposed as virtually useless, as an electrolytic water

which can also be effectively used, and to provide an apparatus for producing

the same.

Another object of the invention is to provide an apparatus in

which any one of an anodic electrolytic water or cathodic electrolytic water

obtained by primary electrolysis or a mixed water of these can be selected and

fed into a secondary electrolyzer so as to be secondarily electrolyzed.

Another object of the invention is to provide a method for producing an

electrolytic water with a remarkably high bactericidal effect.

In order

to accomplish the aforementioned objects, in a method for producing an

electrolytic water, according to one aspect of the present invention, a water is

electrolyzed into an anodic electrolytic water and a cathodic electrolytic water

in a primary electrolyzer having an area provided with an anode and an area

provided with a cathode divided by a separating membrane, and a water produced

in the primary electrolyzer is secondarily electrolyzed in a secondary

electrolyzer.

Furthermore, according to another aspect of the present

invention, an apparatus is provided for producing an electrolytic water, which

apparatus includes a primary electrolyzer provided with an anode and a cathode

and a separating membrane for dividing the primary electrolyzer into an area

containing the anode and an area containing the cathode, a secondary

electrolyzer provided with an anode and a cathode and a separating membrane for

dividing the secondary electrolyzer into an area containing the anode and an

area containing the cathode. An outlet for primary anodic electrolytic water

connects the area containing the anode of the primary electrolyzer to a first

switching valve, an outlet for a primary cathodic electrolytic water connects to

the area containing the cathode of the primary electrolyzer to a second

switching valve and a combined water passage connects the first switching valve

with the second switching valve. A secondary inlet connects the combined water

passage at one end with the secondary electrolyzer at its other end. Further, an

outlet for a secondary anodic electrolytic water is connected to the area

containing the anode in the secondary electrolyzer, and an outlet for a

secondary cathodic electrolytic water is connected to the area containing the

cathode in the secondary electrolyzer.

According to another aspect of

the invention, in the method for producing an electrolytic water, a primary

anodic electrolytic water is secondarily electrolyzed to produce a secondary

anodic electrolytic water, and the secondary anodic electrolytic water is

electrolyzed to produce a tertiary anodic electrolytic water.

BRIEF

DESCRIPTION OF THE DRAWING

Preferred embodiments of the present

invention will hereinafter be described with reference to the accompanying

drawing.

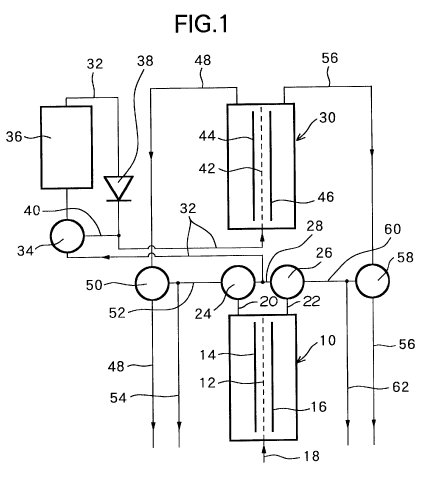

FIG. 1 illustrates an apparatus used for producing an

electrolytic water according to the present invention.

The interior of a

primary electrolyzer 10 is divided into two areas by a separating membrane 12,

in one area of which an positive electrode is provided, and in the other area of

which a negative electrode is provided. The primary electrolyzer 10 is provided

with a primary inlet 18 for receiving a raw water, an outlet 20 for a primary

anodic electrolytic water communicating with the area containing the positive

electrode 14, and an outlet 22 for a primary cathodic electrolytic water

communicating with the area containing the negative electrode 16.

In the

primary electrolyzer 10, the anodic electrolytic water produced at the positive

electrode 14 is removed through outlet 20 as the primary anodic electrolytic

water, i.e., the acid water, and the cathodic electrolytic water produced at the

negative electrode 16 is removed through outlet 22 as the primary cathodic

electrolytic water, i.e., the alkaline water.

The outlet passage 20 for

the primary anodic electrolytic water is connected to a first switching valve

24, the outlet 22 for the primary cathodic electrolytic water is connected to a

second switching valve 26, and a combined outlet 28 connects the first switching

valve 24 with the second switching valve 26.

In addition to the primary

electrolyzer 10, a secondary electrolyzer 30 is provided, and a secondary inlet

passage 32 connects the secondary electrolyzer 30 to the mid-point of the

combined outlet 28. That is, an electrolytic water produced in the primary

electrolyzer 10 is fed into the secondary electrolyzer 30 through the secondary

inlet passage 32. Mid-way of the secondary inlet 32, a third switching valve 34,

chlorine remover 36, and a check-valve 38 are provided in sequence toward the

secondary electrolyzer 30. The chlorine remover 36 has a filter for removing

chlorine using activated carbon or the like. A bypass passage 40 connects the

third switching valve 34 with the secondary incoming passage 32 between the

check-valve 38 and the secondary electrolyzer 30.

The secondary

electrolyzer 30 has the same construction as the primary electrolyzer 10. The

interior of the secondary electrolyzer 30 is divided into two areas by a

separating membrane 42, in one of which areas an anode 44 is provided, and in

the other area a cathode 46 is provided. A secondary anodic electrolytic water

outlet 48 is connected to the area where the anode 44 of the secondary

electrolyzer 30 is disposed, and the anodic electrolytic water electrolyzed in

the secondary electrolyzer 30 is removed through the secondary anodic

electrolytic water outlet 48. A fourth switching valve 50 is provided in the

secondary anodic electrolytic water outlet 48, and an anodic electrolytic water

communicating passage 52 connects the fourth switching valve 50 with the first

switching valve 24. An anodic electrolytic water inlet 54 is connected to the

anodic electrolytic water communicating passage 52.

A secondary cathodic

electrolytic water outlet 56 is connected to the area where the negative

electrode 46 of the secondary electrolyzer 30 is disposed, and the cathodic

electrolytic water electrolyzed in the secondary electrolyzer 30 is taken out

through the secondary cathodic electrolytic water passage 56. A fifth switching

valve 58 is provided on the secondary cathodic electrolytic water outlet 56, and

a cathodic electrolytic water communicating passage 60 connects the fifth

switching valve 58 with the second switching valve 26. A primary cathodic

electrolytic water outlet 62 is connected to the cathodic electrolytic water

communicating passage 60.

An electronic controller (not illustrated)

controls the power supply and voltage regulation for the primary electrolyzer

and the secondary electrolyzer 30 and the switching operations of the switching

valves 24, 26, 34, 50, and 58.

The operation of the apparatus will now

be described, first, for the case wherein only the anodic electrolytic water

produced in the primary electrolyzer 10 is electrolyzed in the secondary

electrolyzer 30. The first switching valve 24 is positioned to connect the

outlet 20 for the primary anodic electrolytic water to the combined outlet 28,

so that the anodic electrolytic water produced in the primary electrolyzer 10 is

fed into the secondary electrolyzer 30 through the combined outlet 28 and the

secondary inlet 32. The third switching valve 34 provided in the secondary inlet

32 is switched so as to connect the combined outlet passage 28 to the bypass 40.

That is, the anodic electrolytic water, produced in the primary electrolyzer 10,

does not pass through the chlorine remover 36.

The second switching

valve 26 is switched to connect the outlet 22 for the primary cathodic

electrolytic water to the cathodic electrolytic water communicating passage 60

only, so that the cathodic electrolytic water produced in the primary

electrolyzer 10 can be routed through the cathodic electrolytic water

communicating passage 60 and through the primary cathodic electrolytic water

outlet 62. The fourth switching valve 50 is switched so as to communicate the

secondary electrolyzer 30 with the atmospheric side of the secondary anodic

electrolytic water outlet 48. The fifth switching valve 58 is switched so as to

communicate the secondary electrolyzer 30 with the atmospheric side of the

secondary cathodic electrolytic water outlet 56.

The cathodic

electrolytic water removed through the primary cathodic electrolytic water

outlet 62 is an electrolytic alkaline water, and this cathodic electrolytic

water is used in the conventional manner. However, the anodic electrolytic water

that is conventionally disposed of as waste is electrolyzed again in the

secondary electrolyzer 30.

The foregoing also applies to a case wherein

the anodic electrolytic water is produced as the major product and is

electrolyzed in the secondary electrolyzer 30. In this case, although the

cathodic electrolytic water by-product is conventionally disposed of as waste,

it too may be electrolyzed in another secondary electrolyzer (not illustrated).

When a water is electrolyzed in the primary electrolyzer 10 and the

secondary electrolyzer 30 with the switching valves 24, 26, 34, 50, and 58

switched as mentioned above, the anodic electrolytic water produced in the

primary electrolyzer 10 is introduced into the secondary electrolyzer 30 from

the first switching valve 24 through the secondary inlet 32 to be electrolyzed

in the secondary electrolyzer 30. The secondary anodic electrolytic water

electrolyzed in the anode compartment of the secondary electrolyzer 30 is

removed through the secondary anodic electrolytic water outlet 48 and through

the fourth switching valve 50. On the other hand, the cathodic electrolytic

water produced in the cathode compartment of the secondary electrolyzer 30, by

electrolysis of the anodic electrolytic water from the primary electrolyzer 10,

is removed through the secondary cathodic electrolytic water outlet 56 and

through the fifth switching valve 58.

Furthermore, the fourth switching

valve 50 may be switched to connect the secondary anodic electrolytic water

outlet 48, leading from the secondary electrolyzer 30, to the anodic

electrolytic water communicating passage 52, 50 that the first switching valve

24 can be connected not only to the combined outlet 28 but also to the anodic

electrolytic water communicating passage 52. In this case, the anodic

electrolytic water produced in the primary electrolyzer 10 and the anodic

electrolytic water produced in the secondary electrolyzer 30 are mixed, and the

mixed anodic electrolytic water is removed through the primary anodic

electrolytic water outlet 54.

Next, the operation of the apparatus will

be described for the case where only the cathodic electrolytic water produced in

the primary electrolyzer 10 is electrolyzed in the secondary electrolyzer 30.

The second switching valve 26 is switched to connect the outgoing passage 22 for

the primary cathodic electrolytic water to the combined outlet 28, so that the

cathodic electrolytic water produced in the primary electrolyzer 10 can be

introduced into the secondary electrolyzer 30 from the combined outlet passage

28 through the secondary inlet 32. The third switching valve 34 provided in the

secondary inlet 32 is switched so as to connect the combined outlet 28 to the

bypass 40. That is, the cathodic electrolytic water produced in the primary

electrolyzer 10 is routed so as not to pass through the chlorine remover 36.

The first switching valve 24 is switched to connect the outlet 20 for

the primary anodic electrolytic water to the anodic electrolytic water

communicating passage 52 only, so that the anodic electrolytic water produced in

the primary electrolyzer 10 can be removed through the anodic electrolytic water

communicating passage 52 and through the primary anodic electrolytic water

outlet 54. The fifth switching valve 58 is switched so as to communicate the

secondary electrolyzer 30 with the atmospheric side of the secondary cathodic

electrolytic water outlet 56. The fourth switching valve 50 is switched so as to

communicate the secondary electrolyzer 30 with the atmospheric side of the

secondary anodic electrolytic water outlet 48.

The anodic electrolytic

water removed through the primary anodic electrolytic water passage 54 is an

electrolytic acid water, and this anodic electrolytic water is put to

conventional uses. However, the cathodic electrolytic water that has

conventionally been disposed of as waste is electrolyzed again in the secondary

electrolyzer 30.

When cathodic electrolytic water which is produced as

the major product is again electrolyzed in the secondary electrolyzer 30,

although the anodic electrolytic water taken would conventionally be disposed as

waste, it may be electrolyzed in another secondary electrolyzer (not

illustrated).

When a water is electrolyzed in the primary electrolyzer

10 and the secondary electrolyzer 30 with the switching valves 24, 26, 34, 50,

and 58 positioned as mentioned above, the cathodic electrolytic water produced

in the primary electrolyzer 10 is introduced into the secondary electrolyzer 30

from the second switching valve 26 through the secondary inlet 32 to be

electrolyzed in the secondary electrolyzer 30. The secondary cathodic

electrolytic water produced in the cathode area of the secondary electrolyzer 30

is removed through the secondary cathodic electrolytic water outlet 56 via the

fifth switching valve 58. On the other hand, the water produced in the anode

area of the secondary electrolyzer 30 from the cathodic electrolytic water

produced in the primary electrolyzer 10 is removed through the secondary anodic

electrolytic water outlet 48 via the fourth switching valve 50.

The

fifth switching valve 58 may be switched to connect the secondary cathodic

electrolytic water outlet 56 on the side of the secondary electrolyzer 30 to the

cathodic electrolytic water communicating passage 60, 50 that the second

switching valve 26 can be connected not only to the combined outlet 28 but also

to the cathodic electrolytic water communicating passage 60. In this

arrangement, the cathodic electrolytic water produced in the primary

electrolyzer 10 and the cathodic electrolytic water electrolyzed in the

secondary electrolyzer 30 are mixed, and the mixed cathodic electrolytic water

is removed through the primary cathodic electrolytic water outlet 62.

In

another embodiment, a mixture of the anodic electrolytic water and the cathodic

electrolytic water produce d in the primary electrolyzer 10 is electrolyzed in

the secondary electrolyzer 30. In this case, the first switching valve 24 is

switched to connect the outlet 20 for the primary anodic electrolytic water to

the combined outlet 28, and the second switching valve 26 is switched to connect

the outlet 22 for the primary cathodic electrolytic water to the combined outlet

28. Thus, the anodic electrolytic water and the cathodic electrolytic water

produced in the primary electrolyzer 10 are mixed in the combined outlet 28, and

this water mixture is routed to the secondary electrolyzer 30 through the

secondary inlet passage 32. The third switching valve 34 provided in the

secondary inlet 32 is switched so as to communicate the combined outlet 28 with

the bypass 40. That is, the cathodic electrolytic water produced in the primary

electrolyzer 10 is routed so as not to pass through the chlorine remover 36.

The fourth switching valve 50 is switched to bring the secondary

electrolyzer 30 into communication with the atmospheric side of the secondary

anodic electrolytic water outlet 48. The fifth switching valve 58 is switched so

as to bring the secondary electrolyzer 30 into communication with the

atmospheric side of the secondary cathodic electrolytic water outlet 56.

Water is electrolyzed in the primary electrolyzer 10 and in the

secondary electrolyzer 30 with the switching valves 24, 26, 34, 50, and 58

positioned as mentioned above. As the result, the anodic electrolytic water and

the cathodic electrolytic water electrolyzed in the primary electrolyzer 10 are

mixed and introduced into the secondary electrolyzer 30 through the third

switching valve 34 and the secondary inlet 32 to be electrolyzed in the

secondary electrolyzer 30. The anodic electrolytic water produced in the anode

area of the secondary electrolyzer 30 is removed via the secondary anodic

electrolytic water outlet 48 via the fourth switching valve 50. The cathodic

electrolytic water produced in the cathode area of the secondary electrolyzer 30

is removed through the secondary cathodic electrolytic water outlet 56 via the

fifth switching valve 58.

The fourth switching valve 50 may be switched

to connect the secondary anodic electrolytic water passage 48 to the anodic

electrolytic water communicating passage 52, so that the first switching valve

24 can be connected not only to the combined outlet 28 but also to the anodic

electrolytic water communicating passage 52. Moreover, the fifth switching valve

58 may be switched to connect the secondary cathodic electrolytic water outlet

56 to the cathodic electrolytic water communicating passage 60, so that the

second switching valve 26 can be connected not only to the combined outlet 28

but also to the cathodic electrolytic water communicating passage 60.

Experiment #1

In experiment 1 a service water is electrolyzed in

the primary electrolyzer 10 and the primary electrolytic water is secondarily

electrolyzed in the secondary electrolyzer 30.

The service water used in

this experiment showed pH 7.6, electric conductivity 160 .mu.S/cm, dissolved

oxygen concentration 8.5 mg/l, oxidation reduction potential 584 mv, and free

dissolved chlorine concentration 0.6 mg/l. The primary electrolyzer 10 was

operated with a water temperature of 21.6.degree. C., water flow rate of 1.41

1/mm, and electrolyzing voltage at 18 V. As the result, a primary anodic

electrolytic water was produced which showed a pH of 4.5, an electric

conductivity of 189 .mu.S/cm, a dissolved oxygen concentration of 10.5 mg/l, an

oxidation reduction potential of 780 mv, a free dissolved chlorine concentration

of 1.3 mg/l, and a primary cathodic electrolytic water was produced which showed

a pH of 9.6, an electric conductivity of 210 .mu.S/cm, a dissolved oxygen

concentration of 6.8 mg/l, an oxidation reduction potential of -153 mv, and a

free dissolved chlorine concentration of 0.2 mg/l.

Only the primary

anodic electrolytic water produced in the primary electrolyzer 10 was

secondarily electrolyzed in the secondary electrolyzer 30, and a secondary

anodic electrolytic water was produced which showed a pH of 3.2, an electric

conductivity of 381 .mu.S/cm, a dissolved oxygen concentration of 14.1 mg/l, an

oxidation reduction potential of 930 mv, a free dissolved chlorine concentration

of 2 mg/l, and a secondary cathodic electrolytic water was produced which showed

a pH of 6.7, an electric conductivity of 141 .mu.S/cm, a dissolved oxygen

concentration of 8.2 mg/l, an oxidation reduction potential of 2 mv, and a free

dissolved chlorine concentration of 0.5 mg/l.

In the secondary anodic

electrolytic water produced by electrolyzing the primary anodic electrolytic

water again in the secondary electrolyzer 30, the dissolved oxygen concentration

increased from 10.5 mg/l to 14.1 mg/l, the oxidation reduction potential changed

from 780 mv to 930 mv, and the free dissolved chlorine concentration changed

from 1.3 mg/l to 2 mg/l. That is, the secondary anodic electrolytic water showed

a higher dissolved oxygen concentration, oxidation reduction potential, and free

dissolved chlorine concentration than the primary anodic electrolytic water.

Therefore, the secondary anodic electrolytic water can be used for its

astringent effect and curative effect in treatment of atopic dermatitis.

Further, the cathodic electrolytic water produced by secondarily

electrolyzing the primary anodic electrolytic water showed a lower oxidation

reduction potential and free dissolved chlorine concentration than the service

water, indicating a suitability for drinking.

On the other hand, when

only the primary cathodic electrolytic water produced in the primary

electrolyzer 10 was secondarily electrolyzed in the secondary electrolyzer 30,

the secondary anodic electrolytic water so produced showed a pH of 8.3, an

electric conductivity of 158 .mu.S/cm, a dissolved oxygen concentration of 9.8

mg/l, an oxidation reduction potential of 38 mv, and a free dissolved chlorine

concentration of 0.9 mg/l. The secondary cathodic electrolytic water so produced

showed a pH of 10.1, an electric conductivity of 312 .mu.S/cm, a dissolved

oxygen concentration of 4.8 mg/l, an oxidation reduction potential of -828 mv,

and a free dissolved chlorine concentration of 0.1 mg/l.

Thus, in the

secondary cathodic electrolytic water produced by electrolyzing the primary

cathodic electrolytic water again in the secondary electrolyzer 30, the

dissolved oxygen concentration decreased from 6.8 mg/l to 4.8 mg/l and the

oxidation reduction potential decreased from -153 mv to -828 mv. Therefore, the

secondary cathodic electrolytic water is preferable to the primary cathodic

electrolytic water for drinking.

The anodic electrolytic water produced

by secondarily electrolyzing the primary cathodic electrolytic water showed a pH

value of 8.3, indicating a slight alkalinity. However, the free dissolved

chlorine concentration was 0.9 mg/l (the average free dissolved chlorine

concentration of the service water is 1.0 mg/1), indicating suitability for

general use as service water.

When a mixture of the primary anodic

electrolytic water and primary cathodic electrolytic water produced in the

primary electrolyzer 10 was secondarily electrolyzed in the secondary

electrolyzer 30, an anodic electrolytic water was produced which showed a pH of

3.84, an electric conductivity of 230 .mu.S/cm, a dissolved oxygen concentration

of 12.6 mg/l, an oxidation reduction potential of 900 mv, and a free dissolved

chlorine concentration of 2 mg/l. A cathodic electrolytic water was produced

which showed a pH of 10.6, an electric conductivity of 250 .mu.S/cm, a dissolved

oxygen concentration of 5.6 mg/l, an oxidation reduction potential of -460 mv,

and a free dissolved chlorine concentration of 0.2 mg/l.

Thus,

secondarily electrolyzing the mixture of the primary anodic electrolytic water

and primary cathodic electrolytic water will raise the dissolved oxygen

concentration of 10.5 mg/l and oxidation reduction potential of 780 mv of the

primary anodic electrolytic water to higher levels, i.e. to a dissolved oxygen

concentration of 12.6 mg/l and an oxidation reduction potential of 900 mv in the

secondary anodic electrolytic water, thus improving the quality of water as

compared to the primary electrolytic acid water. Furthermore, the secondary

electrolysis lowers the dissolved oxygen concentration of 6.8 mg/l and oxidation

reduction potential of -153 mv of the primary cathodic electrolytic water, i.e.

to a dissolved oxygen concentration of 5.6 mg/l and an oxidation reduction

potential of -460 mv in the secondary cathodic electrolytic water, thus

improving the quality of the water as compared to the primary electrolytic

alkaline water.

Experiment #2

In experiment 2 service water of

the same quality as in experiment 1 was electrolyzed with the same water flow

rate as in experiment 1 and with an electrolyzing voltage of 28 V. As a result,

a primary anodic electrolytic water was produced which showed a pH of 3.52, an

electric conductivity of 389 .mu.S/cm, a dissolved oxygen concentration of 12.4

mg/l, an oxidation reduction potential of 820 mv, and a free dissolved chlorine

concentration of 1.5 mg/l. Further, a primary cathodic electrolytic water was

produced which showed a pH of 10.6, an electric conductivity of 313 .mu.S/cm, a

dissolved oxygen concentration of 6.8 mg/l, an oxidation reduction potential of

-758 mv, and a free dissolved chlorine concentration of 0.3 mg/l.

Next,

only the primary anodic electrolytic water produced in the primary electrolyzer

10 was secondarily electrolyzed in the secondary electrolyzer 30, and a

secondary anodic electrolytic water was produced which showed a pH of 2.7, an

electric conductivity of 940 .mu.S/cm, a dissolved oxygen concentration of 22.5

mg/l, an oxidation reduction potential of 1030 mv, and a free dissolved chlorine

concentration of 10 mg/l. This secondary anodic electrolytic water had a high

free dissolved chlorine concentration as compared to the free dissolved chlorine

concentration obtained in experiment 1 (2 mg/l), indicating a strong

bactericidal activity.

In addition, a cathodic electrolytic water was

produced which showed a pH of 9.4, an electric conductivity of 101 .mu.S/cm, a

dissolved oxygen concentration of 6.2 mg/l, an oxidation reduction potential of

-825 mv, and a free dissolved chlorine concentration of 0.4 mg/l. Although this

cathodic electrolytic water showed a slightly high free dissolved chlorine

concentration, it is still within the standard and can be an ideal drinking

water.

When only the primary cathodic electrolytic water produced in the

primary electrolyzer 10 was secondarily electrolyzed in the secondary

electrolyzer 30, an anodic electrolytic water was produced which showed a pH of

7.1, an electric conductivity of 72 .mu.S/cm, a dissolved oxygen concentration

of 21.9 mg/l, an oxidation reduction potential of 671 mv, and a free dissolved

chlorine concentration of 8 mg/l. This anodic electrolytic water was neutral and

very high in dissolved oxygen concentration (double that of a conventional

oxygen saturated water), and can be used as a bacteriostatic agent.

The

secondary cathodic electrolytic water thus produced showed a pH of 11.4, an

electric conductivity of 521 .mu.S/cm, a dissolved oxygen concentration of 4.2

mg/l, an oxidation reduction potential of -863 mv, and a free dissolved chlorine

concentration of 0.01 mg/l. This secondary cathodic electrolytic water shows a

high pH value. However, it contains a slight amount of metal ions (sodium ion,

potassium ion, etc.) paired with the hydroxyl groups and, therefore, the

cathodic electrolytic water is unstable in pH, easy to drink without a sense of

rejection, and can be an anoxic water that does not cause a disorder due to

strong alkalinity.

When the anodic electrolytic water and cathodic

electrolytic water produced in the primary electrolyzer 10 were mixed, and the

mixed water showed a pH of 10.62, an electric conductivity of 207 .mu.S/cm, a

dissolved oxygen concentration of 7.8 mg/l, an oxidation reduction potential of

-97 mv, a free dissolved chlorine concentration 0.66 mg/l, which is a weak

alkaline water with an oxidation reduction potential significantly lower than

the raw water. This mixed water was secondary electrolyzed in the secondary

electrolyzer 30, and an anodic electrolytic water was produced which showed a pH

of 3.1, an electric conductivity of 402 .mu.S/cm, a dissolved oxygen

concentration of 26.7 mg/l, an oxidation reduction potential of 950 mv, and a

free dissolved chlorine concentration of 7.5 mg/l. Thus, the dissolved oxygen

concentration and oxidation reduction potential of the secondary anodic

electrolytic water were higher than in the primary anodic electrolytic water,

and thus the quality of the secondary anodic electrolytic water was higher than

that of the primary electrolytic acid water.

The secondary cathodic

electrolytic water produced from the mixed water showed a pH of 11.2, an

electric conductivity of 353 .mu.S/cm, a dissolved oxygen concentration of 5

mg/l, an oxidation reduction potential of -844 mv, and a free dissolved chlorine

concentration of 0.5 mg/l. This secondary cathodic electrolytic water is

effective for sterilization and oxidation and is an electrolytic alkaline water

with a strong reduction power. Thus, the dissolved oxygen concentration and

oxidation reduction potential of the secondary cathodic electrolytic water are

lower than in the primary cathodic electrolytic water, and its quality is better

than that of the primary electrolytic alkaline water.

In order to remove

the dissolved chlorine from the electrolytic alkaline water, the water was

passed through an activated carbon filter, and the result was that, although the

pH value decreased 0.2 to 0.5, the electric conductivity and the dissolved

oxygen concentration were almost unchanged, and the oxidation reduction

potential increased by 50 to 100 mv, all of which values are within ranges

effective for drinking.

Next, the method of removing chlorine contained

in the water primarily electrolyzed, prior to secondary electrolysis, will be

described. In FIG. 1, first, the third switching valve 34 provided in the

secondary inlet 32 is switched so as to pass the water from the secondary inlet

32 in sequence through the chlorine remover 36 and the check-valve 38.

The electrolytic water produced in the primary electrolyzer 10 is passed

through the chlorine remover 36 containing a chlorine removal filter of an

activated carbon or the like. After the free dissolved chlorine is removed, the

water is electrolyzed in the second electrolyzer 30. When the primary anodic

electrolytic water was electrolyzed in the electrolyzer 30 and the secondary

anodic electrolytic water so produced with chlorine filtering was compared to

that produced without chlorine filtering, the pH value was seen to be higher by

0.3, the electric conductivity lower by about 200 .mu.S/cm, the oxidation

reduction potential lower by about 100 mv, and the dissolved oxygen

concentration and free dissolved chlorine concentration did not change. And, in

the cathode area, the pH value decreased by about 1, the electric conductivity

increased by about 30 .mu.S/cm, the oxidation reduction potential decreased by

about 100 mv, and the free dissolved chlorine concentration decreased to 0.1.

When the secondary cathodic electrolytic water produced with chlorine

filtering was compared with that produced without chlorine filtering, the pH

value was seen to be lower by about 3 and the neutral water changed into a

distinctively acidic water, the electric conductivity increased by about 10

.mu.S/cm, the oxidation reduction potential increased by about 100 mv, and the

dissolved oxygen concentration and the free dissolved chlorine concentration did

not change. In the cathode area, the pH value did not change, the electric

conductivity decreased by about 50 .mu.S/cm, and the oxidation reduction

potential and free dissolved chlorine concentration decreased to 0.1.

Consequently, secondarily electrolyzing the primary electrolytic water

after filtering out the chlorine contained therein tends to increase the pH and

to decrease the oxidation reduction potential in the secondary anodic

electrolytic water; however, the value remains within a range showing the

astringent effect, and the secondary cathodic electrolytic water shows a

decrease in the dissolved chlorine so that it becomes an electrolytic alkaline

water more suitable for drinking.

Thus, by chlorine filtering between

the primary and secondary electrolysis, the free dissolved chlorine

concentration in the secondary electrolytic water is decreased to less than 15

ppm.

Experiment #3

In the forgoing embodiment, secondary

electrolysis was described; however, when a tertiary electrolysis or still

higher-order electrolysis is performed, a higher-order electrolytic anodic water

shows a higher dissolved oxygen concentration and oxidation reduction potential,

and a higher-order cathodic electrolytic water shows a lower dissolved oxygen

concentration and oxidation reduction potential.

In a third experiment

tertiary electrolysis was performed, that is, the tertiary electrolysis was

applied to the waters obtained through the secondary electrolysis. Among the

tertiary electrolytic waters, the tertiary anodic electrolytic water produced by

electrolyzing a secondary anodic electrolytic water, in turn produced by

electrolyzing the primary anodic electrolytic water, was found to display a

distinctive sterilization effect.

The experimental data for the service

water (raw water), the primary anodic electrolytic water, the secondary anodic

electrolytic water, and the tertiary anodic electrolytic water was as follows.

______________________________________

oxidation

dissolved

free dissolved

reduction

oxygen chlorine

pH potential

concentration

concentration

______________________________________

service water

7.19 574 9.6 0.6

primary a.w.

2.56 871 11.6 6

secondary a.w.

1.87 907 16.4 6

tertiary a.w.

1.45 1071 24.6 15

______________________________________

"a.w." is an abbreviation for anodic ectrolytic water.

From the results of this experiment, a big change is seen in the

pH between the primary anodic electrolytic water and the secondary anodic

electrolytic water, i.e. 2.56 versus 1.87, which is a big change, while the

oxidation reduction potential and dissolved oxygen concentration changed only

slightly, and the free dissolved chlorine concentration remained unchanged. In

contrast, between the secondary and the tertiary anodic electrolytic water, the

pH decreased to less than 1.5 (the acidity became very strong) and, furthermore,

the oxidation reduction potential increased by about 160 mv, the dissolved

oxygen concentration increased to about 1.5 times, and the free dissolved

chlorine concentration increased 2.5 times.

Thus, when the secondary

anodic electrolytic water is electrolyzed to produce the tertiary anodic

electrolytic water, the pH, oxidation reduction potential, dissolved oxygen

concentration, and free dissolved chlorine concentration are significantly

changed to values exhibiting a bactericidal effect, and the tertiary anodic

electrolytic water displays a very strong bactericidal activity that had not

been obtained up to the present.

As described hereinabove, according to

the present invention, an electrolytic water in compliance with its intended use

can be transformed into an electrolytic water more effectively used by repeating

electrolysis more than two times, and the electrolytic acid water for drinking

or the electrolytic alkaline water for sterilization, which have conventionally

been disposed of as having virtually no use, can be transformed into

electrolytic waters which can be effectively used.

Furthermore, since

the chlorine contained in the primary electrolytic water is filtered out before

the secondary electrolysis, a special step for the electrolytes and the like

becomes unnecessary; and therefore, an electrolytic water can be obtained easily

and reliably which has an oxidation reduction potential and a dissolved oxygen

concentration in compliance with its intended use and a dissolved chlorine

concentration no higher than needed.

Moreover, the tertiary anodic

electrolytic water possesses significantly better values for pH, oxidation

reduction potential, dissolved oxygen concentration, and free dissolved chlorine

concentration which show a bactericidal effect, and a water can be produced

which has a much stronger bactericidal activity than that previously obtained.

While specific embodiments of the present invention have been

illustrated and described herein, it is realized that numerous modifications and

changes will occur to those skilled in the art. It is therefore to be understood

that the appended claims are intended to cover all such modifications and

changes as fall within the true spirit and scope of the invention.

* * * * *

![[US Patent & Trademark Office, Patent Full Text and Image Database]](United States Patent 5,858,202.files/patfthdr.gif)

![[Home]](United States Patent 5,858,202.files/home.gif)

![[Boolean Search]](United States Patent 5,858,202.files/boolean.gif)

![[Manual Search]](United States Patent 5,858,202.files/manual.gif)

![[Number Search]](United States Patent 5,858,202.files/number.gif)

![[Help]](United States Patent 5,858,202.files/help.gif)

![[Bottom]](United States Patent 5,858,202.files/bottom.gif)

![[View Shopping Cart]](United States Patent 5,858,202.files/cart.gif)

![[Add to Shopping Cart]](United States Patent 5,858,202.files/order.gif)

![[Image]](United States Patent 5,858,202.files/image.gif)

![[US Patent & Trademark Office, Patent Full Text and Image Database]](United States Patent 5,858,202.files/patfthdr.gif)

![[Home]](United States Patent 5,858,202.files/home.gif)

![[Boolean Search]](United States Patent 5,858,202.files/boolean.gif)

![[Manual Search]](United States Patent 5,858,202.files/manual.gif)

![[Number Search]](United States Patent 5,858,202.files/number.gif)

![[Help]](United States Patent 5,858,202.files/help.gif)

![[Bottom]](United States Patent 5,858,202.files/bottom.gif)

![[View Shopping Cart]](United States Patent 5,858,202.files/cart.gif)

![[Add to Shopping Cart]](United States Patent 5,858,202.files/order.gif)

![[Image]](United States Patent 5,858,202.files/image.gif)